Chemical reactions are central to many processes in nature and industries. Whether it is the combustion of fuel, the formation of life-sustaining molecules, or the production of vital chemicals for manufacturing, chemical reactions are essential. However, these reactions often need external influences to proceed at a practical rate. This is where catalysts come into play. Catalysts are substances that significantly increase the rate of chemical reactions without being consumed in the process, making them indispensable in both natural and industrial contexts. In this article, we will explore the vital role of catalysts in accelerating chemical processes, how they work, and their applications across different industries.

Understanding Chemical Reactions and the Need for Catalysts

To appreciate the significance of catalysts, it is important to understand the basic principles of chemical reactions. A chemical reaction occurs when two or more reactants interact to form products, and this process typically requires energy to initiate. This energy is known as the activation energy—the energy needed to break bonds in the reactants to allow the formation of new bonds in the products.

In many cases, the activation energy required for a reaction to proceed is quite high, which means the reaction may be slow, inefficient, or might not occur at all under normal conditions. For instance, without a catalyst, reactions that are essential in nature or in industrial processes could be prohibitively slow, making it difficult to meet the demands for production or energy. Catalysts serve as facilitators in these scenarios, reducing the activation energy required and allowing reactions to occur at a faster rate.

What is a Catalyst?

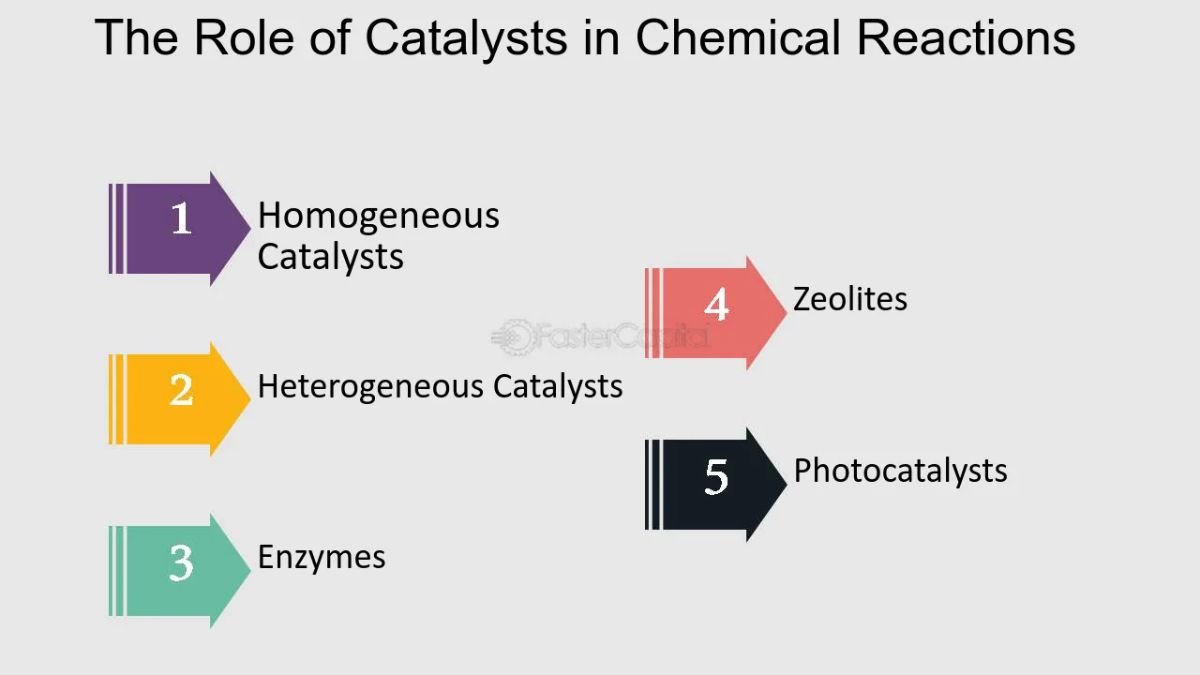

A catalyst is a substance that increases the rate of a chemical reaction by lowering the activation energy. It does this without being consumed in the reaction, meaning it can be reused multiple times. There are two main types of catalysts:

- Homogeneous Catalysts: These catalysts exist in the same phase (solid, liquid, or gas) as the reactants. For example, in a reaction where both the catalyst and the reactants are in solution, the catalyst will facilitate the reaction directly within the solution.

- Heterogeneous Catalysts: These catalysts are in a different phase than the reactants. For instance, solid catalysts are often used in reactions involving gaseous or liquid reactants. The solid catalyst provides a surface for the reaction to take place, promoting a faster reaction.

The role of the catalyst can be seen as that of a facilitator, providing an alternative pathway for the reaction with a lower activation energy. In doing so, it accelerates the reaction without altering the final outcome of the process. This makes catalysts crucial for both efficiency and sustainability, especially in large-scale chemical processes.

How Catalysts Work: The Mechanisms of Action

Catalysts work by providing a surface or environment where reactants can interact more readily. This is typically achieved through a mechanism known as adsorption, where reactants are temporarily bound to the catalyst surface. Once bound, the reactants are more likely to undergo the necessary bond-breaking and bond-forming steps that lead to the creation of the product.

For homogeneous catalysts, the interaction often involves the formation of a temporary complex with the reactants, which then undergoes a series of transformations to form the product. The catalyst then regenerates to its original state after the reaction is completed.

In heterogeneous catalysis, the catalyst provides a surface where reactants are adsorbed, leading to the formation of intermediate complexes. These intermediates are often more reactive than the original reactants, and once the reaction is complete, the products are desorbed from the surface, leaving the catalyst unchanged.

A key feature of catalysts is that they do not alter the equilibrium of the reaction. This means they do not affect the concentration of reactants or products at equilibrium, but they speed up the rate at which equilibrium is reached.

Types of Catalysts and Their Applications

Catalysts are employed in a vast array of chemical processes, from industrial manufacturing to biological systems. Let’s take a closer look at the different types of catalysts and their specific applications:

1. Industrial Catalysts

Catalysts play a critical role in many large-scale industrial processes. One of the most important applications is in the petrochemical industry, where catalysts are used to refine crude oil into usable products such as gasoline, diesel, and other chemicals. For example, in the hydrocracking process, a catalyst helps break down large hydrocarbon molecules into smaller, more useful molecules. This is achieved using a heterogeneous catalyst, typically a solid metal or metal oxide that facilitates the breaking of carbon-carbon bonds in hydrocarbons.

In the manufacturing of ammonia, the Haber-Bosch process uses an iron catalyst to speed up the reaction between nitrogen and hydrogen to produce ammonia, which is then used for fertilizers. This process is vital for global agriculture and requires high temperatures and pressures. The use of a catalyst allows for the process to occur at a much more feasible rate and efficiency.

2. Biological Catalysts (Enzymes)

Enzymes are nature’s catalysts. These are biological molecules, typically proteins, that accelerate biochemical reactions within living organisms. Enzymes are highly specific and are involved in nearly every biochemical reaction in cells, from digestion to DNA replication.

For example, in the human body, the enzyme amylase speeds up the breakdown of starches into sugars during digestion. The specificity of enzymes is one of their most remarkable features. Each enzyme typically catalyzes only one type of reaction, ensuring precision in metabolic processes.

The use of enzymes as catalysts has also found applications in industry. Enzymes are used in the food and beverage industry to improve processes like fermentation, cheese-making, and brewing. They are also used in detergents, where they help break down stains and dirt more efficiently at lower temperatures.

3. Environmental Catalysts

Catalysts are also integral in environmental protection, particularly in reducing harmful emissions. The catalytic converter in cars is a classic example of a catalyst used to reduce air pollution. This device contains precious metals such as platinum, palladium, and rhodium, which act as catalysts to convert harmful gases like carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful emissions, such as carbon dioxide and water vapor.

In industrial settings, scrubbers and catalytic reactors are used to treat exhaust gases, removing toxic substances before they can be released into the atmosphere. The ability to use catalysts to minimize environmental impact is a growing area of importance, especially as industries face increasing regulations on emissions.

The Future of Catalysts in Accelerating Chemical Processes

The role of catalysts in accelerating chemical processes is more important than ever. With growing concerns about sustainability and environmental impact, research in catalyst development is focused on improving efficiency, reducing energy consumption, and minimizing waste. Researchers are exploring new materials, such as nanocatalysts, which have increased surface areas that can provide faster reaction rates. Additionally, the design of biomimetic catalysts, which mimic the efficiency and specificity of enzymes, is another promising area of study.

Moreover, catalysts are becoming crucial in the field of green chemistry, which aims to design chemical processes that reduce or eliminate the use of hazardous substances. New catalytic methods are being explored for sustainable manufacturing processes, such as the use of renewable feedstocks and the reduction of harmful byproducts.

Conclusion

Catalysts are indispensable in the acceleration of chemical processes, playing a crucial role in everything from industrial manufacturing to biological systems. By lowering activation energy and providing efficient pathways for reactions, catalysts allow for faster, more efficient, and sustainable chemical reactions. As industries continue to innovate and as the demand for more environmentally friendly solutions grows, the role of catalysts will undoubtedly remain central to advancing both scientific knowledge and practical applications in numerous fields. The future of catalyst technology looks promising, with new materials and methodologies poised to revolutionize chemical processes across industries.